Glazing and Glass Services

We are the South West’s glass installation and production specialists for commercial contracts, new builds, refurbishments, repair, heritage and restoration glazing projects. Servicing commercial, residential and trade customers.

Glazing Services

With our no obligation free quotations service and technical team who can advise on glass safety, glass loads, and all aspects of building regulations glazing requirements including Document Q and Document K you can be assured of the very best professional service.

Read More

Our glazing teams hold certificates for the following:

- CSCS – A health and safety test that shows minimal health and safety awareness

- PASMA – (Prefabricated Access Suppliers and Manufacturers Association) Competence at erecting a tower scaffold.

- IPAF – (International Powered Access Federation), Competence that the individual is trained in the use of various MEWPS (Mobile Elevating Work Platforms) for example a scissor lift or cherry picker.

- MTC – (Minimum Technical Competencies) Trained and competent in fenestration

- DBS – (Disclosure and Barring Service) – checks the criminal background on an individual – usually required in schools and places where there are vulnerable individuals present.

Glass Cutting

Our group cutting tables enable us to cut single sheets glass 3 mm – 19 mm thick, measuring 3210 mm x 2550 mm and laminated glass 6000 mm x 3000 mm. With edge deletion for soft coat glasses our cutting capability can be tailored to your exact requirements

Read More

Using CAD files from customer templates we are able to cut complex shapes for use in commercial, trade, residential and architectural projects. Everything from a unique table top to high end insulated glass units. For more information about our glass cutting process please get in touch.

Toughening

Toughened glass is a safety glass with increased strength both physically and thermally. Glass that has been toughened is 4 to 5 times stronger than annealed.

Read More

All toughened glass supplied from Cornwall Glass is kite marked to BSEN12150. We toughen from 4mm to 19mm in thickness and up to 4,500mm x 2,150mm in size in house.

Toughened glass is used in a variety of demanding applications such as stairs or balustrading. At Cornwall Glass, we have a state-of-the-art production sites that ensure all our products are produced with maximum strength. This together with our technical expertise allows us to deliver specialist oversize units for your commercial, trade residential and architectural projects.

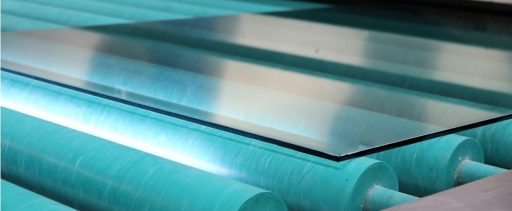

Laminating

Laminated Glass is manufactured by bonding two or more layers of quality float glass together (under a heat and pressure process) with an interlayer of polyvinyl butyral (PVB). Laminated glass is an ideal glass for applications were safety is required.

Read More

Laminating glass provides a stronger, more structurally safe glass panel, that if broken, holds the glass fragments together. Perfect for any structural glass requirement. We can produce laminated glass panels in sizes up to 6m x 3.2m.

CNC Processing

Our in house CNC glass cutting capabilities enable production of high quality, intricate designed glass processing. We are able to cut your glass to any shape and design using CAD drawings and templates or computer design to exact and precise cutting production.

Read More

Below are the cutting and processing capabilities for our CNC machines.

Straight and Shaped edge work – Flat, Arriss and Polished – Bullnose 19 mm, Pencil 4mm and 6mm.

Internal Cut Outs – Extractor holes, socket cut outs. Min 6mm internal radius. Min 13mm for internal polished radius.

Drilling Capabilities – Fixings holes, decorative holes, starting from 4mm diameter 30mm minimum requirement for polished hole.

*Pro line digital scanner for exact, scale templating, converts to a CAD file. Enabling us to take wide range of template types

Brilliant Cutting and Engraving – Production of intricate designs and lines onto glass and mirror.

Milling Tool – Enables us to rout out a complex, intricate, variety of shapes and bespoke designs out of glass.

Shape Bevelling– Specialist service allowing bevelled edges on straight and curved glass and mirror.

CNC Capabilities – Glass thickness 2mm – 19mm. Pane Size up to 3300mm x 2050mm.

Polishing

We offer straight edge polishing with cerium oxide for a high quality finish. Our state-of the art polishing will give your glass an impressive flat polish.

Read More

Our polishing process stands out for its extraordinary production speed while ensuring the best quality finish.

This technique can be used to give a highly polished edged finish to glass. The polishing angle can be altered to your exact specification. Our straight edge polishing machines can cope with massive 6m x 3m glass panel.

Finishes: Bullnose, Bevelled, Mitre, Flat and Arris, Smoothed

Technical details:

Maximum glass size: 6m x 3m

10 polishing and edging wheels

Glass thickness: 4-25mm

Painted Glass

Back painted glass has allowed interior designers freedom of expression when developing concepts for rooms and spaces.

Read More

Giving colour to glass, back painting is a stylish and durable solution that can be applied to a variety of your interior glass requirements. Cornwall Glass can provide back painting for glass panels of sizes up to 6m x 3.2m to any given colour, either in BS or RAL numbers. Used predominantly for glass splash-backs for great effect, back painted glass can also be applied in double glazed units. Our back painted glass can also be used for structural bonding.

The great design factor of back painted glass is complimented by its easy cleaning and tremendous durability. When painted on toughened glass, it is also heat resistant to approximately 200 degrees centigrade, ideal for customising your kitchen and bathroom spaces.

Window Repair

Cloudy, blown or misted window glass can be replaced with new double glazed units matched sympathetically to existing glazing in your property.

Read More

Replacement glass units in PVC, Wood or Aluminium frames can be easily fitted by one or more of our professional glazing team. Single, putty glazed panes of glass can also be replaced with like for like glass maintaining the overall aesthetics of any building even older buildings. For any advice on replacement glass and glazing please do get in touch.

Bevelling

Bevelling is a decorative finish usually applied to the perimeter of the glass. Bevelled glass is typically made from 6mm float glass.

Read More

The width of the bevel can be varied depending on the desired effect. The Bevell finish acts as prisms creating an interesting colour diffraction which both highlights the glass work and provides a spectrum of colours which would ordinarily be absent in clear float glass.

Drilling and Cut Outs

Cornwall Glass has capability for drilling holes into glass of varying thickness from 4mm – 19mm.

Read More

Hole sizes start from 3mm on float glass. We can cut holes to any* size you require. Please contact us to discuss your requirements. *Please the size of the hole that can be drilled is dependent on the thickness of the glass.

Countersunk drill holes: This is where a further angle is cut into the glass, which when a drill piece/screw is used the head of the screw is in-line with the glass, essentially being a flat surface with no raises from the screw heads.

Heat Soaking

This essentially requires that the glass is heated to a very high temperature, 290°C, and left for a time long enough to fracture a large proportion of the panes which may otherwise fracture in service.

Read More

It is a process recommended for glass used in high risk areas where breakage may result in serious injury; sloping overhead canopies (inside pane only), bolt fixed structural glass assemblies and free standing balustrading. The risk is greatly reduced but due to the nature of glass it can never be completely eliminated. To read more about our heat soaked glass please click here.

Water Jet

Our state of the art Waterjet cutter can cut glass into intricate, precise shapes, quickly and economically.

Read More

Our Waterjet cutting is perfect for quick cutting of large units, special shapes and bespoke glass projects. Used predominantly for socket cutouts (wall mounted splashbacks), door hinge cut outs and notching the 3 axis cutter allows it to cut any 2D shape out of glass for design or template.

Due to its low heat conductivity and brittleness, glass is not easy to process. The risk of breakage has to be minimized during production due to tensions and micro-cracks caused during the production process.

Cutting glass with conventional methods comes with significant drawbacks due to relatively low scribing quality (micro-cracks, chipping) and accuracy.

Thickness capabilities, from 2mm to a maximum of 100mm.

Maximum pane size 3870mm x 1750mm.

* Please note this process is for annealed glass only

Heat Treated

A specialist process to increase the mechanical and thermal strength of glass making it twice as tough as annealed glass.

Read More

The strengthening process increases the mechanical and thermal strength of the glass making it twice as tough as annealed glass.

The glass is heated to a uniform temperature of approximately 650 °C to 700 °C in our Efco furnace. Ceramic rollers move the glass through the furnace at a regulated speed to ensure temperature uniformity and minimal distortion.

Acid Etching

Designs are etched into the glass using acid.

Read More

By using this process it gives the glass a greater capability for pattern variety. Acid etching can be used for traditional and contemporary designs with varying transparency levels. The diffusion of light through this decorative glass gives truly creative finish.

Sandblasting

Sandblasted glass is produced by spraying sand at high velocities over the surface of the glass.

Read More

This gives the glass a translucent surface, which is usually rougher than that obtained by etching. During sandblasting, areas that are to remain transparent are masked for protection. The depth and degree of the translucency of the sand-blasted finishing vary with the force and type of sand used.

The sandblasting technique is used to obscure visibility through glass, but the glass continues to still transmit light as it is diffused through the surface. Patterns and designs can be created using a mask which resists the abrasive force of the grit from the sandblaster. The mask can be hand cut or computer cut depending on the design.

Traditional Stained Glass

Using traditional methods our skilled and knowledgeable team are able to produce stained glass and leaded glass to order.

Read More

We have the capability to manufacture and fit heritage and contemporary stained glass windows, listed properties, new builds and self-build projects. With many years of experience we pride ourselves in the work that we undertake, be it a simple repair to complex and intricate leaded light.

Cat and Dog Flaps

We can advise, supply and fit cat and dog flaps into glass doors and windows even if they are double glazed.

Read More

Feeling safe in your home is paramount, so leaving a door or window open for your beloved pets to come and go may not be a very secure solution. With many chip operated dog and cat flaps available you can have peace of mind and happy pets. We can produce a sealed glass unit with a cut out hole (also sealed) so there is no compromise with your windows glass efficiency. The cat or dog flap will fit securely within the cut out unit. For any advice on cat and dog flap, glass door and window installations please do get in touch.

01752 756580 Plymouth@cornwallglassmanufacturing.co.uk

3 Beechwood Way, Langage, Plymouth, PL7 5HH

01726 66325 StAustell@cornwallglassmanufacturing.co.uk

Stennack Road, Holmbush Industrial Estate, St Austell, Cornwall, PL25 3JQ

01278 781500 Highbridge@cornwallglassmanufacturing.co.uk

Walrow Industrial Estate, Brue Way, Highbridge, TA9 4AW

01872 276697 Truro@cornwallglass.co.uk

Chyvelah Road, Threemilestone, Truro, TR3 6AZ

01326 375124 Penryn@cornwallglass.co.uk

Commercial Road, Penryn, TR10 8AQ

01736 360174 Penzance@cornwallglass.co.uk

Poniou Way, Longrock Industrial Estate, Penzance, TR20 8HX

01726 874564 StAustellGlazing@cornwallglass.co.uk

Stennack Road, St Austell, PL25 3JQ

01752 605500 PlymouthTC@cornwallglass.co.uk

3 Beechwood Way, Langage, Plymouth, PL7 5HH

01392 364364 Exeter@cornwallglass.co.uk

7-10 Bittern Units, Bittern Road, Sowton Industrial Estate, Exeter, EX2 7LW

01935 412300 Yeovil@cornwallglass.co.uk

22 Garrett Road, Lynx Trading Estate, Yeovil, BA20 2TJ

0117 9710101 Bristol@cornwallglass.co.uk

Units 1-3, 306 Broomhill Road, Brislington, Bristol, BS4 5RG