Energy surcharges, which can flex and adapt to changing market conditions, are fundamentally a good idea. So, why does Mark Mitchell, Chair of Cornwall Group, fear that the current model could be forcing some businesses under.

The volatility of the energy market, and the effect this has on energy-intensive industries such as glass, is creating a headache for many companies, trying to keep their businesses profitable.

One tool that tracks short term pricing volatility, but doesn’t bake-in price rises, is the energy surcharge. While its presence on invoices is seldom welcomed, its intention is well meaning.

“As a transparent mechanism, the surcharge is good,” Mark Mitchell, Our Chair of the Cornwall Group, says. “It tracks the issue – in this case, energy prices – and it disappears when things settle. A price increase, on the other hand, rarely disappears.

“If the surcharge is understandable and in plain English then the market accepts it.”

Mark’s concern is that the energy surcharge, which has become prevalent in the glass and glazing industry, isn’t based on a standard mechanism, which is causing greater chaos as a result.

Some companies will base the surcharge on the price of oil on the London Stock Exchange, while others will track gas.

Stability is key for Cornwall Group, which has spent 45 years weathering economic storms.

“There could be a number of reasons for this,” Marks says. “For example, after the European Commission found that some of the major glass manufacturers has been colluding on price, those same companies probably went out of their way to avoid any similarity in pricing structures.

“Or, because they are headquartered in different jurisdictions, they link the surcharges to the market they are in, rather than a standard universal rate across Europe.”

Whatever the reason, the end result is the same: pricing chaos.

“When you have lots of different mechanisms for working out energy surcharges, all coming out at different times of the month, with different lead-in times, it all creates uncertainty and confusion,” Mark says. “And it’s not terribly transparent.”

“This doesn’t fit with the main principle of a surcharge, which is to offer stability and certainty.”

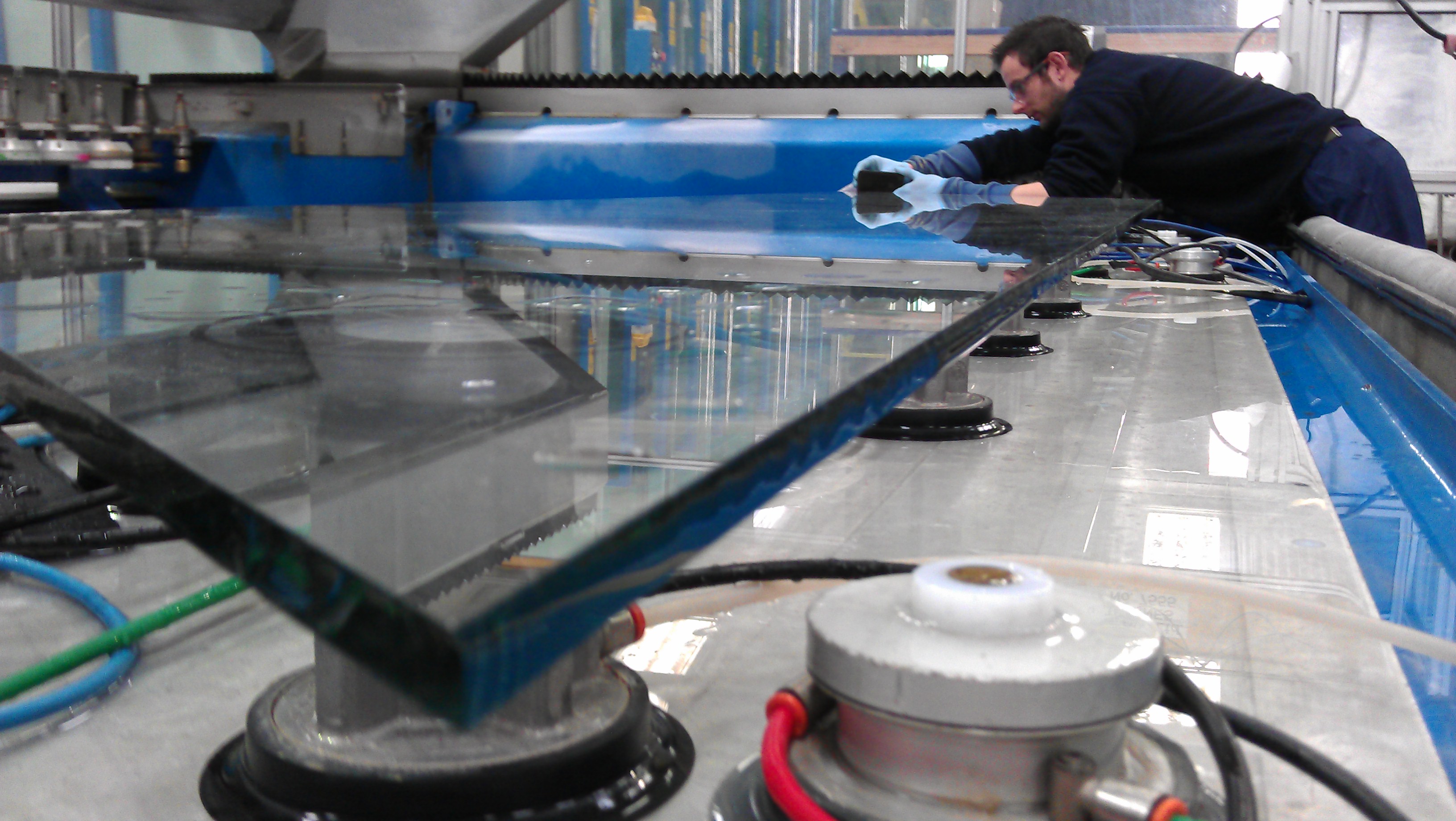

Our Group comprises Cornwall Glass Manufacturing (which offers a diverse range of options in IGUs and single glass, with three manufacturing facilities in St Austell, Highbridge and Plymouth), glass merchanting business Mackenzie Glass and retail-focused Cornwall Glass & Glazing.

Each of our companies buys glass from Saint-Gobain Glass, Pilkington, AGC, Guardian Glass, and other global suppliers, and we regularly update our accounting software to manage the different mechanisms for establishing an accurate surcharge correctly.

“The other day, I saw there were three different surcharges – one for 5p, one for 12p, and one for 17p – for a single product,” Mark says. “Each surcharge was dependent on when the order was taken, and some things take longer to manufacture and deliver than others.

“What’s more, our customers are scratching their heads wanting to know why the prices keeping changing on invoices that sometimes arrive on the same day.”

So, while the principle of a surcharge is far better than a price rise, the chaotic management of energy surcharges in the UK glass industry could have serious ramifications further down the line.

“The direct upshot of this is that some companies could be losing out on £1000s by not passing on surcharges to customers in a timely and accurate fashion,” Mark explains.

“We’ve always been reactive and giving people lots of notice about price increases and energy surcharges. But recently that has been very difficult. In some cases, we are being told about a price increase on the 28th of the month that comes into force on the 1st of the following month. That gives us just two days to change our computer systems and prepare customers for a change in product price.”

“But if you are not prompt with passing on the price increases, you can end up subsidising your customers. And the surcharges are like a fiddler’s elbow – up and down and all over the place. They are very hard to keep a track of.”

Mark argues that while our companies are managed to iron out the disruptions caused by badly managed energy surcharges, not all companies have those same resources.

For example, many are owner/managed and very hands on – they can be found on the trade counter, or in the factory with their colleagues – and so they spend less time paying attention to surcharges and updating accounting software.

Our companies manage to iron out disruptions caused by energy surcharges, not all companies have those same resources.

“I speak to companies who are genuinely on the back foot when glass manufacturers give little notice to surcharge increases, and don’t flex their prices accordingly,” Mark says. “They tell me that they don’t want to be adjusting their accounting software every five minutes.

“But that’s dangerous. If they are charging a 10p surcharge when they are being charged 17p by their supplier, then it won’t take long before they start to see their margin eroded. They’ll look at their monthly sales and say they’re busy, but they are not actually making any money. And a lot of them won’t have the software or the staff levels to notice their profitability dropping.

“Many companies are going to get to the end of their financial year and find they have something of a black hole because those increased costs will have accumulated, and not been passed on.”

Stability is key for Cornwall Group, which has spent 45 years weathering economic storms. We has also spent time working with owners of glass companies looking to exit strategically.

“We’ve always been open to buying the right company, and there have been some promising developments,” Mark says. “I’ve no doubt that we will be bigger by this time next year.”

For more information, please call 01726 66325 email info@cornwallglass.co.uk or log on at www.cornwallglass.co.uk .